Everything you need to know about LEGO’s recycled plastic prototype brick & sustainability efforts

2

2

Last week, LEGO unveiled the very first prototype 2×4 brick made from recycled plastic – a groundbreaking achievement and stepping stone towards LEGO’s eventual goal of using plant-based or recycled materials for all their elements by 2030.

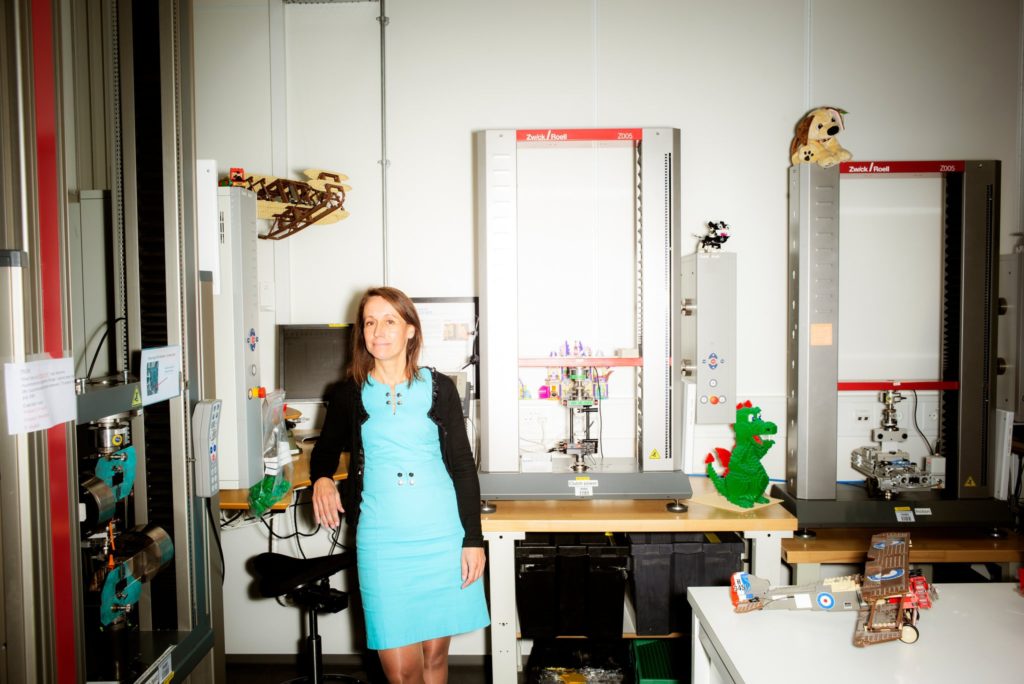

I was lucky enough to sit in on a roundtable where we got to speak to Tim Brooks, Vice President of Environmental Responsibility and Nelleke van der Puil, Vice President of Materials, who were spearheading this project to research and develop methods to use recycled plastic for LEGO bricks.

I was accompanied by Blocks Magazine, New Elementary Brick Fanatics, Hoth Bricks and Brickfinder and we collectively contributed the below questions.

The following interview has been condensed and edited for brevity, and I’ve grouped the questions in these themes:

- On the process, and effort to get to the prototype recycled brick

- On whether bricks made of recycled plastic will come close to regular LEGO bricks?

- On reducing The LEGO Group’s carbon footprint

- On other sustainable initiatives such as packaging

To learn more about LEGO’s sustainability efforts, visit https://www.lego.com/en-au/aboutus/sustainability

On the process, and effort to get to the prototype recycled brick

How important is recycling and sustainability, and is this something you hear from consumers?

Tim: It’s massively growing over the last five years particularly.

We’re now getting thousands of letters from our adult fans and from kids – sometimes saying great, we were really happy about Plants from Plants, but also challenging us, saying we want you to do more.

“We want you to remove single use plastic. We want you to use more recycled material. We want you to design more sustainable STEAM sets as well. So it’s massive important for kids.

It’s not our fans, we see even more traction from our employees.

Just the other day, I got a call from the Head of Facilities and he’s like, how do I cover this Parking Lot with solar panels?

I didn’t have to persuade him to do it. He was like, how do I do it? I’m ready, I’ve got the money. Let’s do this together.

That was one of those signs that sustainability is becoming truly embedded in this company when people are actively doing it on their own.

What were some of the development challenges you faced in creating this prototype?

Nelleke: We added things to the plastic in order to make it suitable for the application. Why? Because if you use PTE as is, it’s not going to work with a brick – I can tell you that cause we tried!

It doesn’t clutch the way it should and you don’t have that very nice click when you put them together.

We know that the friction between the bricks is very high, so it’s very difficult to take the bricks apart once you have assembled them.

Secondly, it is not very sturdy, so it is not safe, if you don’t do the magic thing that we did to it.

The third thing that you should also be aware of – we also looked at the durability of the brick. We’re testing at different temperatures to see what does hold. So at 50 degrees, even if you have the additives in there, it just doesn’t stay, it falls apart and the clutch force goes down.

Then there is also cleaning. We want you to be able to clean the bricks. We know that some consumers are washing their bricks, so we have to make absolutely sure that it looks glossy afterwards.

The impact strength and safety is also considered. If you put a weight on it, does it then fall apart or not? Does it break? In what way does it break? Does it break with sharp points and you cannot use it?

I can tell you also that with PET, it is a big challenge. We had to do all these iterations to get all the properties in the right range and that takes a very long time, because if you change one thing, then the other thing might drop. So it is optimisation across many parameters.

Has LEGO collaborated and been exchanging knowledge and findings with other companies who are also on this sustainability journey?

Nelleke: We have been speaking to other companies that are using ABS and are looking to close the loop on ABS, whether its sourcing from recycled source of ABS.

If we talk about bigger sustainability challenges, we have exchanged a lot with quite a few brands. LEGO is part of a consortium with various brands where these topics are discussed.

We also look for opportunities to collaborate – we’re now in such an advanced state, so we’re now seeing some potential here and there where we can collaborate.

We always share our findings with these companies because we believe that we can all benefit from it.

Were there any near misses during the initial phases that made you go back to the drawing board?

Nelleke: We looked at colourability and gloss quite late in the process. We were really focused on the function, safety and also durability.

The colourability and gloss were the most difficult challenges in the end which made us look back a couple of times. I can tell you, it is a journey and has sometimes been a tough journey – we were nearly there and we had to go back.

We felt that we were nearly there and we were almost celebrating, but then we had to iterate again.

On whether bricks made of recycled plastic will come close to regular LEGO bricks?

Consumers tend to associate the word “recycled” with low quality – how will LEGO seek to address those concerns?

Tim: I think recycled materials don’t have to be low quality. I think many people are still emotionally scarred by recycled toilet paper 20 years ago or whatever. I think it’s not just emotional scarring, but the issue is that I think they don’t have to be low quality.

I think if you look at empty bottles now, it would be hard to tell the difference between a recycled bottle and a bottle made out of virgin plastic.

There are leading premium goods manufacturers out there who are using recycled materials, and most people wouldn’t know that.

In terms of cost, our goal is to be consistent on cost with bricks. In terms of our R&D, some things will cost a bit more. Some things will cost a bit less. But at least the guiding principle is to provide cost consistency into the bricks.

One of the things we want to find out from the prototype is, of course, how people view recycled materials – what they like about them, what they want to see in a recycled material.

But ultimately, you know, the future is, we believe for our portfolio is a combination of recycled and bio-based materials. We’ve been pretty clear about that from the beginning.

Does that include consideration for long-term durability?

Nelleke: When we started looking at materials, we actually had no idea how to study this because we’ve never done it before.

We just knew that bricks that we have today are long lasting so we had to devise a way to test this on a shorter time period and also come up with scenarios that would be representative of the lifetime and how you use bricks, and storage.

We did the wildest where we exposed the bricks to light in the southern area in France, measured the temperature of the bricks during transport, and also during storage so we knew what are the maximum temperatures. Moisture is a very important one here – plastic also deteriorates when exposed to high temperature and moisture.

It’s been quite a journey for us.

How much consumer testing has been done? Would every day consumers be able to tell these recycled LEGO bricks apart from regular bricks?

Nelleke: We are we would love to hand them to consumers, but we believe it’s still too early.

We are planning to hand them to consumers soon. Tim and I have been discussing this and we think that within 18 to 24 months we will be able to get them in the hands of consumers.

I’m sure you would see the difference in the bricks. This is not the final version.

They will clutch, equally well. There will be some differences, I’m sure.

They’re not going to be ugly at all, and you’re going to feel that it’s good quality. I very much like them!

Tim: I think there’s something in these discussions whether it’s on colour or sound, there’s also opportunities to make new shapes or new colours out of PET because of the material properties, or even new colours that we haven’t used before

It’s more, what can the material do for us that ABS can’t do for us today?

If recycled plastic becomes a real product, will it be able to match LEGO’s existing colour palette, especially since LEGO fans are so passionate about colour consistency?

Nelleke: One of the reasons why we have so many iterations (over 250), is to make the colouring possible. We had to add a lot of additives to the plastic in order to make it suitable for the application, as safe as it is now, and also amenable to moulding.

By adding all these additives, you would also impact the colour. What we’re seeing now today is that we definitely do not have the formulations to get the right colour in and we will have to work with our colour developers, companies that are supplying our colour today to solve this.

That will be one of the challenges. We know that we are, working against very high targets and we love our colours as well. But I cannot guarantee you that it’s going to work, right? Its a matter of developing and it’s a big challenge.

With moulds, is the goal to re-use existing moulds, or will you have to make completely new moulds?

Nelleke: For each new material, we will have to make new moulds. So, you can imagine that it also is a huge effort and that’s why if we would really transition into these materials, big scale, it’s going to take a very long time.

Will this new recycled plastic be used for transparent parts?

Nelleke: This is not going to be suitable for transparent parts. The reason for that is that we have to put all these additives in to make it suitable for the building function, so we’ll have to look out for other materials.

With ABS, you’re able to have different formulas to achieve different levels of rigidity for different functions, such as bars. Will this new plastic be able to do the same?

Nelleke: The different functionalities will most likely not be covered by one plastic. We, now have ABS of course, which covers a lot of functionalities and we have additional other plastics – 20 different plastics that we apply in our own production.

We think that this plastic, the rPET will cover the knobs and tubes and we’ll have to see how far we can get from this.

This is a starting point, of course and we will expand and see what we can do, for instance, to the design of the elements.

You probably know that there are many, many different varieties of the 2 x 4 brick. I think we have 80 designs of the 2 x 4 brick, so we have to make minor changes in the mould in order to make it fit.

The element design is something that we can work with and we will do what we call, robust element design with these new materials.

Then we’ll have to see how far we can stretch the application of this material to the existing designs and functions.

Was one of the materials that you used recycled LEGO bricks?

Nelleke: That’s a very good question, and obviously we’re also looking into that but not the brick itself.

We’re focused on the durability of the brick, so we’re looking at other ABS sources to recycle from which would definitely be in scope for us.

You might also see something coming up later if we’re successful with that.

Tim: That’s one of the challenges when people ask “why don’t you just recycle LEGO bricks?”

We say, no, we don’t want to recycle LEGO bricks, we want LEGO bricks to be re-played with.

We’re trying to promote reuse rather than recycling of LEGO bricks. That’s where the Lego Replay program in the US and Canada comes in and we really want to scale that as well and encouraging the fact that people pass it down, or donate it

Do you see LEGO shifting more towards recycled bricks in the future, or will there be a balance with regular ABS?

Tim: I think that’s an unknown future. We are definitely focusing very, very hard on recycled material at the moment.

We know bio-based plastic can play a role, but none of these materials are a silver bullet.

Bio-based needs to be grown, ideally from waste materials. We would call them 2nd or 3rd generation biomaterials and not food grade, but they still need to be grown, watered, and fertilised and they still require transport.

We know that biomass materials aren’t simple on their own, but we are definitely putting a lot of focus on the recycled material.

We want to be one of the most responsible users of plastic.

We think plastic is a great material. We’re pretty open about that but it has to be used in the right context – to be durable, high quality and in a reusable application.

That’s why we’re also removing single use plastic from our packaging, because we want to be very solid on how we use plastic in the right way.

Have you also considered moulding them into other iconic shapes and forms like, say, a minifigure? Is that an easier job if it were turned into a minifigure instead of a 2×4 brick?

Nelleke: We’ve had many discussions about this!

We tried it and we can do it, but it’s not ready for us to hand to consumers yet.

There is also another plastic in the minifigure, which we haven’t made sustainable yet which then leads to another discussion about whether this is truly a sustainable plastic minifigure.

Of course, we truly believe that a 2×4 brick is the iconic LEGO element. We believe that if we can tackle this one, we can tackle a lot because a lot of the building system is connected to this and the volumes are big which is why we’re focusing on this one first.

Tim: That’s the thing with minifigures – it may feel like a brick, but its actually nine bricks/components which makes the challenge even harder.

On reducing The LEGO Group’s carbon footprint

What’s LEGO’s stance on being carbon neutral or carbon negative?

Tim: We already committed to being carbon neutral by 2022 across our own operations. That’s about 10-11% of our footprint is our own factories, our own shops and our own offices.

We’re rolling out solar panels across our factories, such as covering our whole Jiaxing (China) factory in solar panels. We’re also investing in offshore wind farms through our parent company.

We’re on track to be carbon neutral by 2022 within our own operations, but that’s only 10-11% of our total footprint.

The rest of it requires engaging our suppliers and our supply chain. We set a science-based target last year, and that’s a 37.5% cut across our entire value chain.

Why 37.5? Why that strange number? That’s our commitment to maintaining the planet within a 1.5 degree warming scenario, which is what the Paris agreement asks us.

For us to play our part, it’s to cut emissions across our value chain by 37.5%.

We are definitely looking towards net zero across our entire portfolio.

What we’re seeking and analyzing at the moment is the standards and robustness of those frameworks in making a commitment because that requires you to go off and do what we would call nature-based solutions and other things like that.

How are you managing the carbon footprint from the manufacturing of these recycled plastic bricks?

Tim: One of the things with these materials and the same with the Plants from Plants is to think end-to-end across the value chain and across the lifecycle assessment because we’re trying to consider all of the inputs that goes into a brick for a bio based material – how is it grown, et cetera.

And the same for the rPET like where does it come from, how does it have to be transported?

Our initial lifecycle assessment would say that around about 65-70% CO2 reduction using rPet versus virgin ABS. That’s a significant number.

Our materials on average (cardboard and plastic) represent about 30% of our total carbon footprint, so we’re responsible for about 1.2 million tonnes of carbon a year.

In this particular version of rPet, we believe we can cut the CO2 footprint of a brick by about 65-70%.

It’s not just a good result from stopping plastic entering the landfill and hopefully stopping plastic entering into nature.

But that’s not always the case – many of the materials we’re looking at are from recycled sources and different sources might have a high carbon footprint which we’re also considering, but as long as we believe we can get to a lower carbon footprint over the long term, this is one that straight out of the gate, we believe that the footprint will be greatly reduced.

On other sustainable initiatives such as packaging

With single-use plastics, will we see single-used polybags completely replaced by paper?

Tim: The goal is to stop using single use plastic by 2025. I mean that is the externally committed goal.

We’re working super hard on that. We’re working on the paper bags and smaller bags as well.

I think we are going to have to look at alternative packaging solutions where they get a lot of stress and abuse on the shelf, so it won’t be a one for one solution.

We might have to look at boxes or tubes and what have you, and we need to be innovative about how we do that.

Are you guys able to influence LEGO sets being designed, for example the LEGO City sets from early 2021 which had EVs, solar panels and recycling stations? Do you work closely with the Design and Product teams?

Tim: We work closely with them and we help them shape the ideas, and that’s the fun bit of the job, as well as all of the other stuff we get to do.

You know, I think it goes back some way now, right back to, you know, the first Vestas turbine with a couple of bio-based elements then expanding it to the Treehouse that we were involved with, you know, helping them shape and scope and then.

You can see this Friends set here, with the solar panel, wind turbine and electric car, you can start seeing sustainability come out in multiple themes

We definitely help guide and shape that. It also comes from our knowledge that kids are writing to us in ever larger numbers as sustainability is a passion point for them.

In particular LEGO City, we know that kids want City to both represent the world that they see around them, which is increasingly EVs and hybrid buses and whatever, but also an aspirational world of one that they could imagine and want it to be want to live in that city.

When I was building City, I was the world I wanted to live in, not necessarily the world that I was surrounded with.. So it’s definitely part of our ideas and going forward and we get involved with those guys.

Do you feel confident in the 2030 target (that all its elements will be made from plant-based or recycled materials) or is that more an aspirational target?

Tim: Someone asked me that today, I think it sounds like it’s all done with this announcement.

Not at all, it’s a massive stretching target and it is still an ambitious target for all of the reasons we’ve been talking about safety, quality, colour, durability, the shininess.

It’s the same with packaging as well – getting paper bags to perform in a strong way and not be punctured.

They’re all big, big challenges. I can’t tell you whether we’ll make it or not.

I can definitely say it’s our aim to make it and we’re putting as much effort as we can behind it.

I think if we put significant financial and people resources behind it, we absolutely hope to.

To learn more about LEGO’s sustainability efforts, visit https://www.lego.com/en-au/aboutus/sustainability

To get the latest LEGO news and LEGO Reviews straight in your inbox, subscribe via email, or you can also follow on Google News, or socials on Facebook, Instagram (@jayong28), Twitter or subscribe to the Jay’s Brick Blog Youtube channel.

To get the latest LEGO news and LEGO Reviews straight in your inbox, subscribe via email, or you can also follow on Google News, or socials on Facebook, Instagram (@jayong28), Twitter or subscribe to the Jay’s Brick Blog Youtube channel.

- LEGO 10341 NASA Artemis Space Launch System and 31212 Milky Way Art join a Space-filled May 2024!

- LEGO Minifigures Series 26 Space QR Box Codes Identification and Weight Guide

- Introducing the new and improved Jay’s Brick Blog!

- Entire LEGO Despicable Me 4 set lineup revealed, including first look at Mega Minions minifigures!

- Here are the winners of the Medieval March contest!