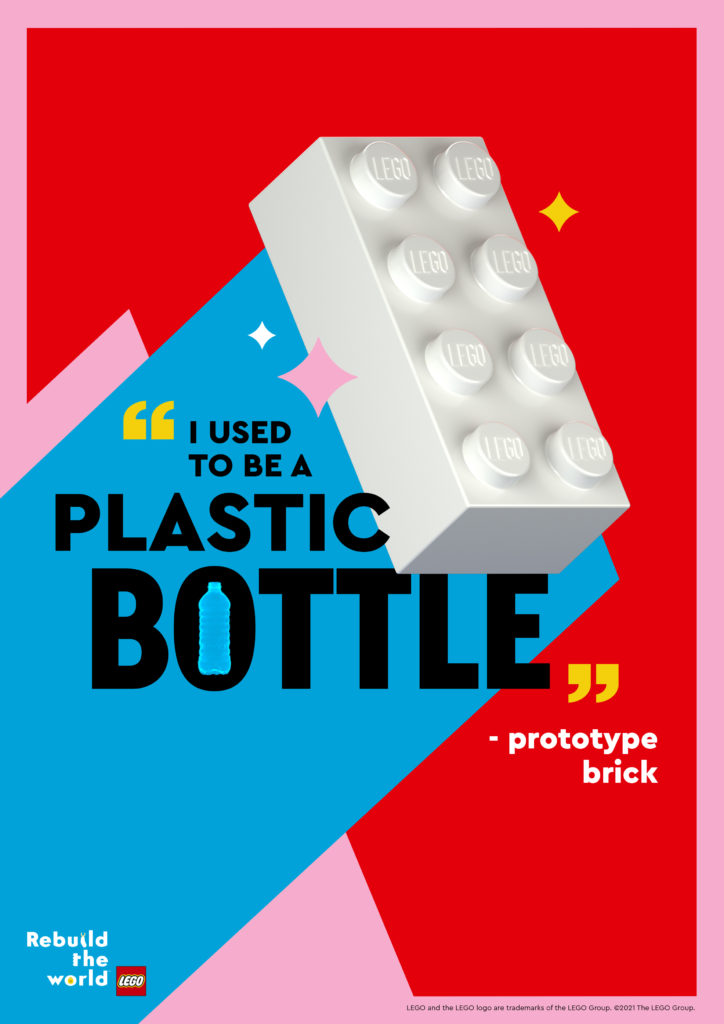

LEGO unveils first prototype brick created from recycled plastic

2

2

These might look like generic grey 2 x 4 bricks, but what you’re seeing here are the very first prototype LEGO brick made completely out of recycled materials, representing a major breakthrough in LEGO’s sustainability efforts.

A team of more than 150 people are working to find sustainable solutions for LEGO products. Over the past three years, materials scientists and engineers tested over 250 variations of PET materials and hundreds of other plastic formulations.

The result is a prototype that meets several of their quality, safety and play requirements – including clutch power.

Maintaining LEGO’s high standards of quality and safety

It will be some time before bricks made from a recycled material appear in LEGO product boxes. The team will continue testing and developing the PET formulation and then assess whether to move to the pilot production phase. This next phase of testing is expected to take at least a year.

In a chat with the team responsible for this project, they did mention that they would love to hand them to consumers, but they are planning on getting it into the hands of consumers in the next 18-24 months.

Tim Brooks, Vice President of Environmental Responsibility said: “We know kids care about the environment and want us to make our products more sustainable. Even though it will be a while before they will be able to play with bricks made from recycled plastic, we want to let kids know we’re working on it and bring them along on the journey with us. Experimentation and failing is an important part of learning and innovation. Just as kids build, unbuild and rebuild with LEGO bricks at home, we’re doing the same in our lab.”

The prototype is made from recycled PET sourced from suppliers in the United States that use US Food & Drug Administration (FDA) and European Food Safety Authority (EFSA) approved processes to ensure quality.

On average, a one-litre plastic PET bottle provides enough raw material for ten 2 x 4 LEGO bricks.

Towards more sustainable products

The patent-pending material formulation increases the durability of PET to make it strong enough for LEGO bricks. The innovative process uses a bespoke compounding technology to combine the recycled PET with strengthening additives.

The recycled prototype brick is the latest development in making the LEGO Group’s products more sustainable.

In 2020, the company announced it will begin removing single-use plastic from its boxes. In 2018, it began producing elements from bio-polyethylene (bio-PE), made from sustainably sourced sugarcane.

Many LEGO sets contain elements made from bio-PE which is perfect for making smaller, softer pieces such as trees, branches, leaves and accessories for minifigures.

Bio-PE is not currently suitable for making harder, stronger elements such as the iconic LEGO bricks.

Brooks said: “We’re committed to playing our part in building a sustainable future for generations of children. We want our products to have a positive impact on the planet, not just with the play they inspire, but also with the materials we use. We still have a long way to go on our journey but are pleased with the progress we’re making.”

The LEGO Group’s focus on sustainable material innovation is just one of several different initiatives the company has in place to make a positive impact. The LEGO Group will invest up to US $400 million over three years to 2022 to accelerate its sustainability ambitions. For more information on how the LEGO Group wants to rebuild the world for the better, visit: LEGO.com/Sustainability

I was lucky enough to sit in a Group Roundtable with Tim Brooks, Vice President of Environmental Responsibility, Nelleke van der Puil, Vice President of Materials, who is also responsible for the sustainable materials program.

Look out for the interview content to be published tomorrow, as I’m still cleaning up the transcript, but here are some interesting tidbits the fan media learned:

- It took over 250 iterations not just for stability, clutch and strength, but to ensure that they got the colour right. Additives were added to the plastic to make it safe, usable and amenable to moulding

- LEGO are also making strides with the reduction of their carbon footprint (materials account for just over 30% of LEGO’s carbon footprint) – with this particular version of rPet (recycled polyethylene terephthalate) – they can cut the CO2 footprint of a brick by about 65%

- LEGO has also committed to being carbon neutral across their owned operations by 2022

- LEGO are exploring new shapes and even new colours out of recycled PET due to its unique properties

- What about minifigures? They have tried and they can do it, but they’ll need a lot more work to make it truly sustainable as there is a different type of plastic used within minifigures.

To read the full interview with LEGO’s Sustainability and Materials team, be sure to check in tomorrow when I’ve cleaned up the transcript and edited it!

To get the latest LEGO news and LEGO Reviews straight in your inbox, subscribe via email, or you can also follow on Google News, or socials on Facebook, Instagram (@jayong28), Twitter or subscribe to the Jay’s Brick Blog Youtube channel.